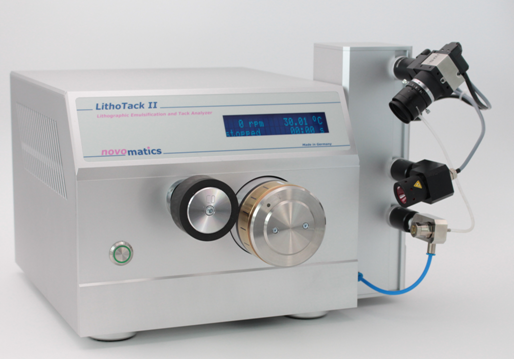

The new LithoTack II is two laboratory instruments in one. On the one hand the LithoTack is a simply to use precision tack measuring instrument on the other the LithoTack II determines water balance behavior of thin ink film under practice relevant conditions.

These and more water balance parameters can be measured quickly and accurately under press conform conditions

- minimal water content for plate cleaning and maximal water content for correct tack (water tolerance range)

- Interaction with hydrophobic and hydrophilic surfaces (for example, plate cleaning up)

- Dynamics of water pickup and water release

- Linetack as function of water content (includes a tack measurement of a dry ink)

- Amount of free surface water

- and more

Most importantly, the LithoTack operating conditions such as speed, film thickness and temperature are similar to those found on a printing press. A test takes a few minutes – so you can characterize and optimize your products quickly, ideally for R&D and QC.

Important questions

- Is there a good interaction between fount and ink?

- How large is the water tolerance range for good print result?

- Will the change to ink B instead ink A or the change to fount Y instead fount X have an essential effect to the print quality?

- Is a bad cleaning up of the plate more caused by the fount or more caused by the ink or more caused by the plate?

- What would be the better ink or the better fount for printing with less water?

- Can I print with less alcohol?

- Is there a higher tendency for free surface water?

- Is there a higher risk for scumming?

More can be answered with the LithoTack II on an early laboratory scale. Modern sensing devices like micro wave water content sensor or high speed tack sensor are scanning the emulsion properties in roller nip – the exact position where an emulsion is created.

The instrument is addressed to R&D, QC and applications engineering. For example, customer’s ink and fount solution may be in same test – you may provide exact information regarding their combined water emulsification performance and so their printability. This qualifies the new LithoTack II to a high beneficial laboratory instrument regarding early cost savings and advanced customer loyalty.

Please don’t hesitate to contact Novomatics for further technical or commercial details.